A Deep Dive into the HeatCore HS20 Hydro Mining System and Whatsminer M63S

Explore a household-friendly hydro mining boiler system.

This article was co-authored by Lauren Lin and Denny Xing

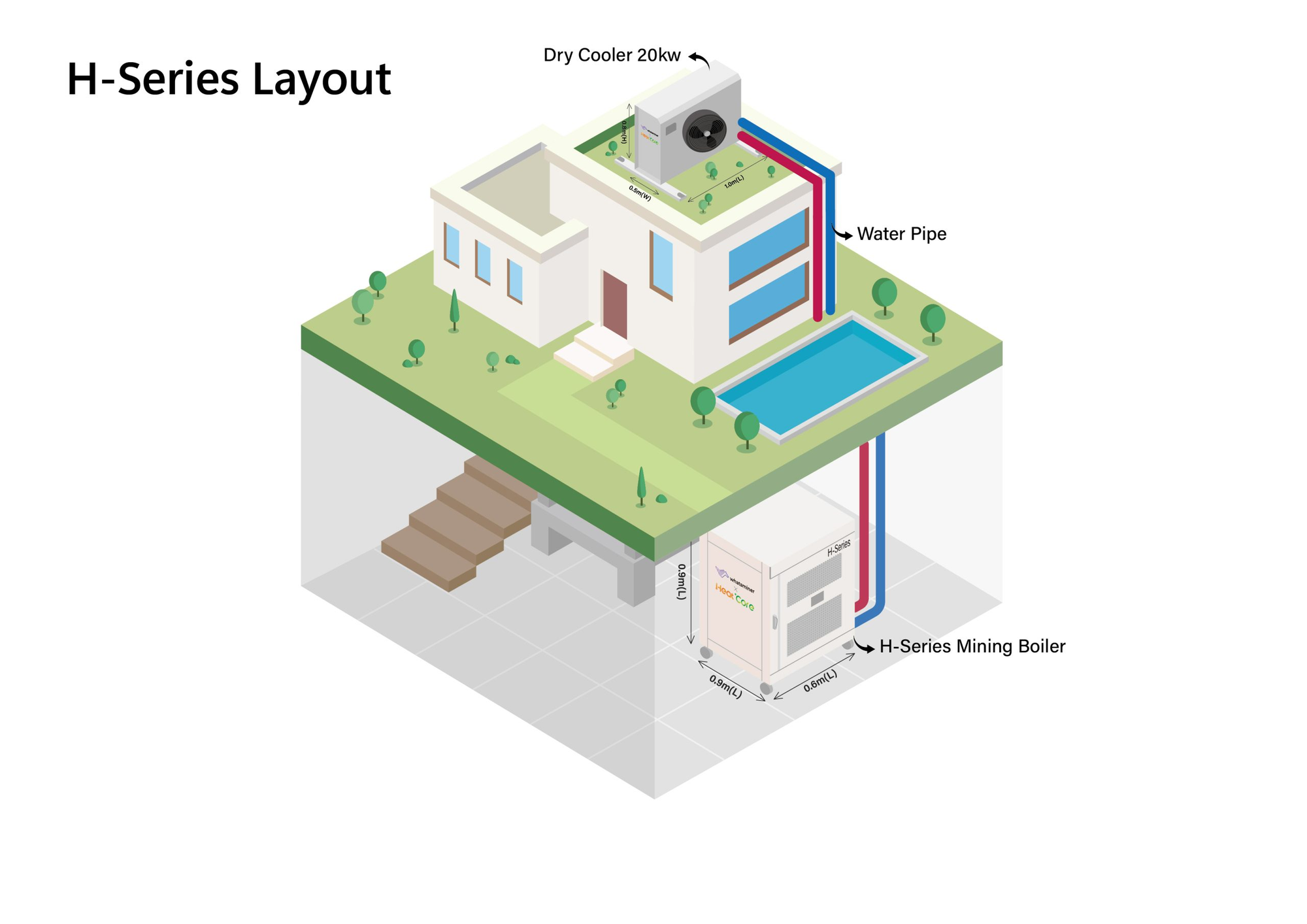

The HeatCore HS20 hydro cooling system caught our eye during an immersion and hydro-cooled bitcoin mine tour, as mentioned in this previous article. Specifically, we were intrigued by its potential to transform home mining. This compact, household-friendly hydro mining system designed by HeatCore should allow its user to mine Bitcoin at home while generating hot water with a 20kW rated heating capacity.

In this article, we’ll take a deeper dive into this innovative hydro system and run it with MicroBT’s latest hydro-cooled model, the Whatsminer M63S.

HS20 Design

Mining Boiler

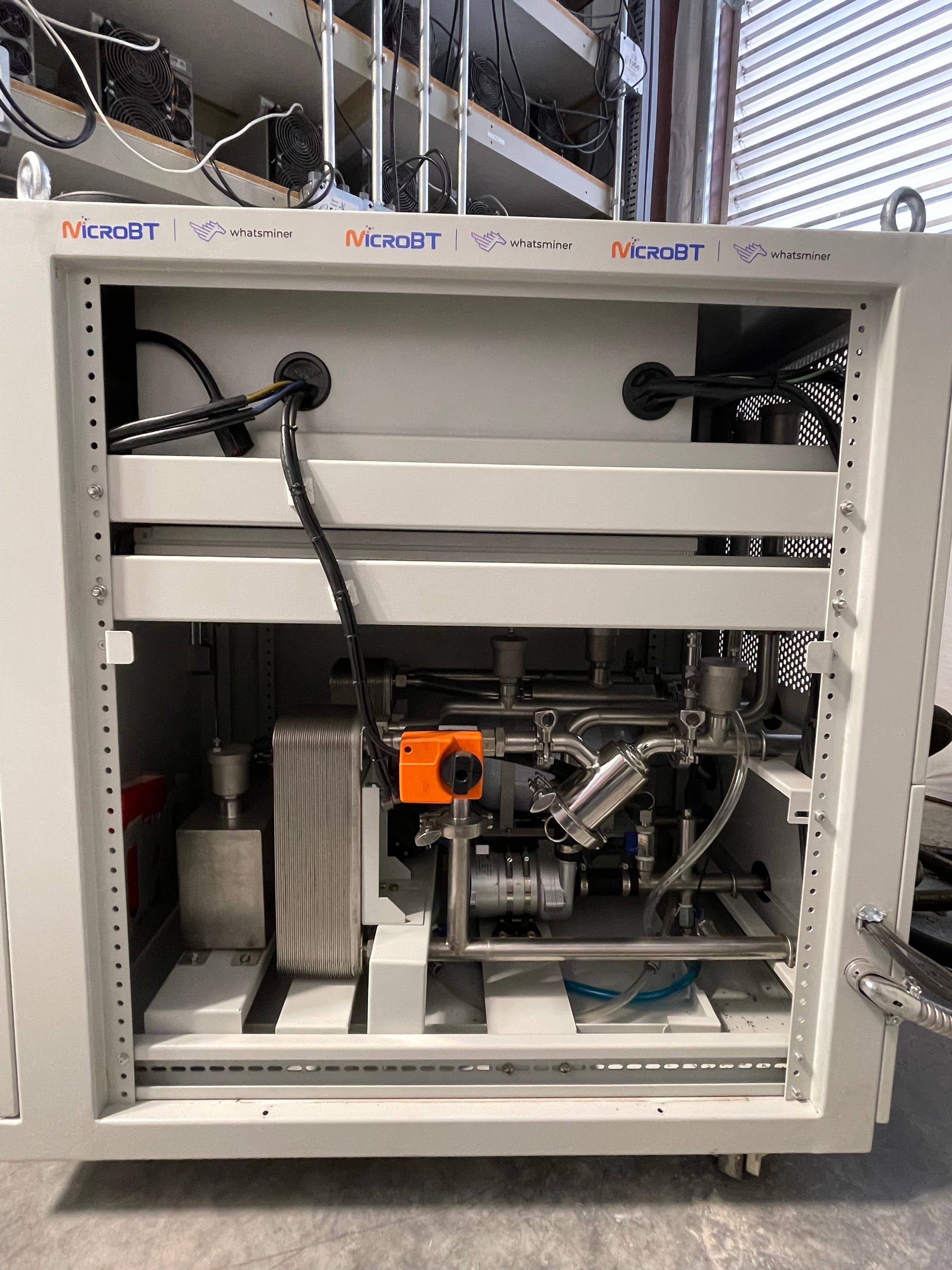

The HS20 is a mobile unit that features built-in wheels for easy maneuvering. Once positioned, we used the adjustable leveling feet at the bottom to ensure the unit was level. This flexibility makes it a great fit for locations like a garage or basement.

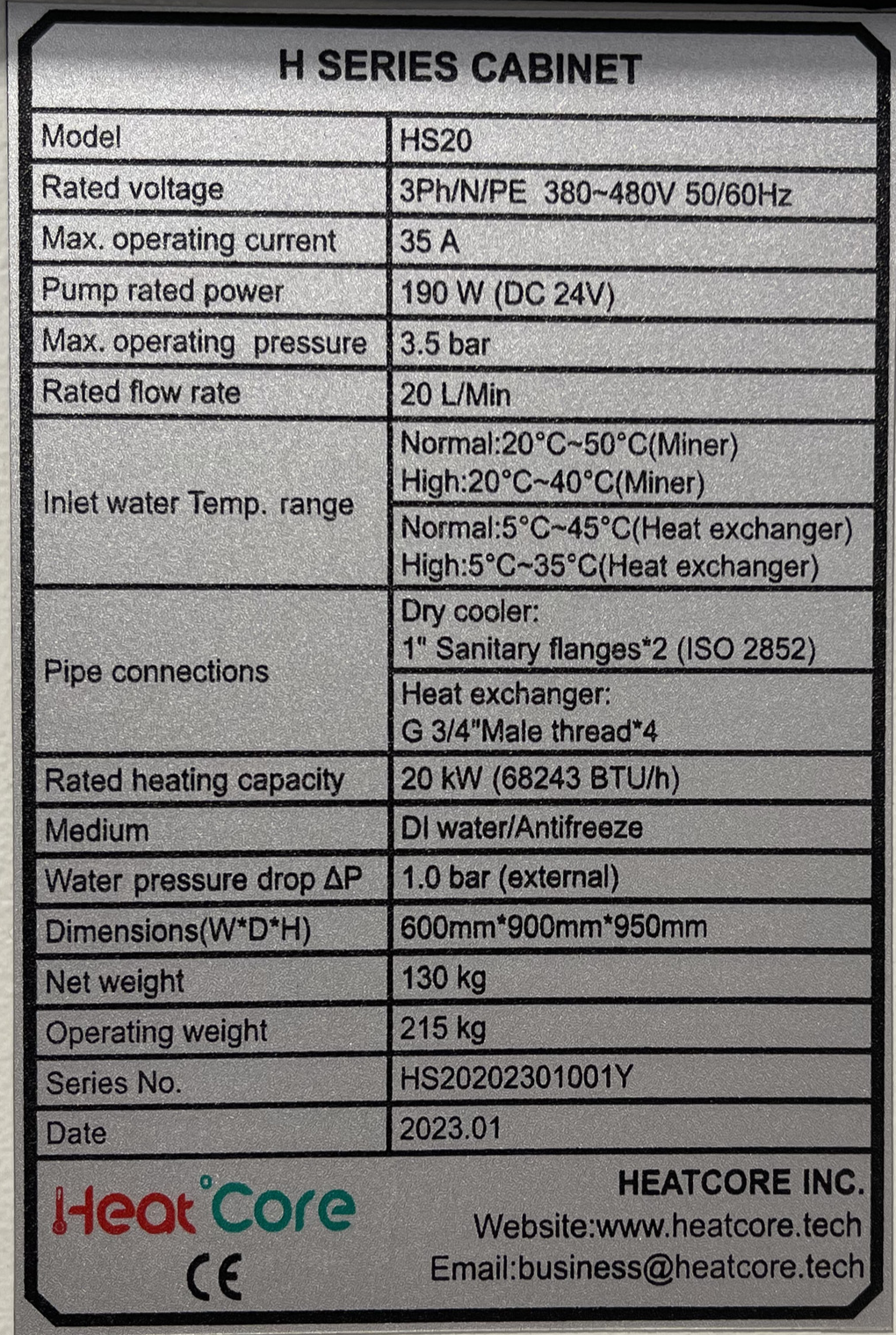

The HeatCore HS20 Boiler is a compact unit, measuring 600mm x 900mm x 950mm and weighing 130kg empty or 215kg with miners running. The devices requires a 3-phase electrical connection ranging from 380V to 480V at 50/60Hz with a maximum operating current of 35A. Additionally, the pump utilizes a DC 24V power supply and has a rated power draw of 190W.

When operating the HS20, HeatCore suggests using deionized (DI) water or antifreeze as coolant, maintaining an ambient temperature between -25°C and 45°C (to avoid freezing), and maintaining a relative humidity (RH) level of 10% to 90% without condensation. It operates optimally at altitudes below 2,000 meters as it will operate at reduced capacity at higher elevations.

To get the HS20 connected to our plumbing system, let’s look at HS20’s two main connectors at the back of the unit:

- Primary Loop (G 3/4 inch external thread): The primary loop uses a standard threaded plumbing connection ( ¾ inch) and comes with caps to keep the pipes clean during transport. Remember to remove these caps before installation.

- Secondary Loop (1 inch sanitary flanges): This loop uses a wider flange connection (1 inch) and also has protective caps for transport. Remove these caps before installation as well.

If you’re installing an HS20, it’s advisable to have a qualified installer to make sure everything is set up correctly. To facilitate future maintenance, users will want to add shut-off valves to both the supply and return lines for the HS20. Additionally, it's important to ensure any pipes connected to the unit are well-supported as the HS20 itself cannot handle the weight of external pipes. Finally, if you live in an earthquake-prone area, you need to consult an engineer to determine if flexible pipe connections are necessary for added protection.

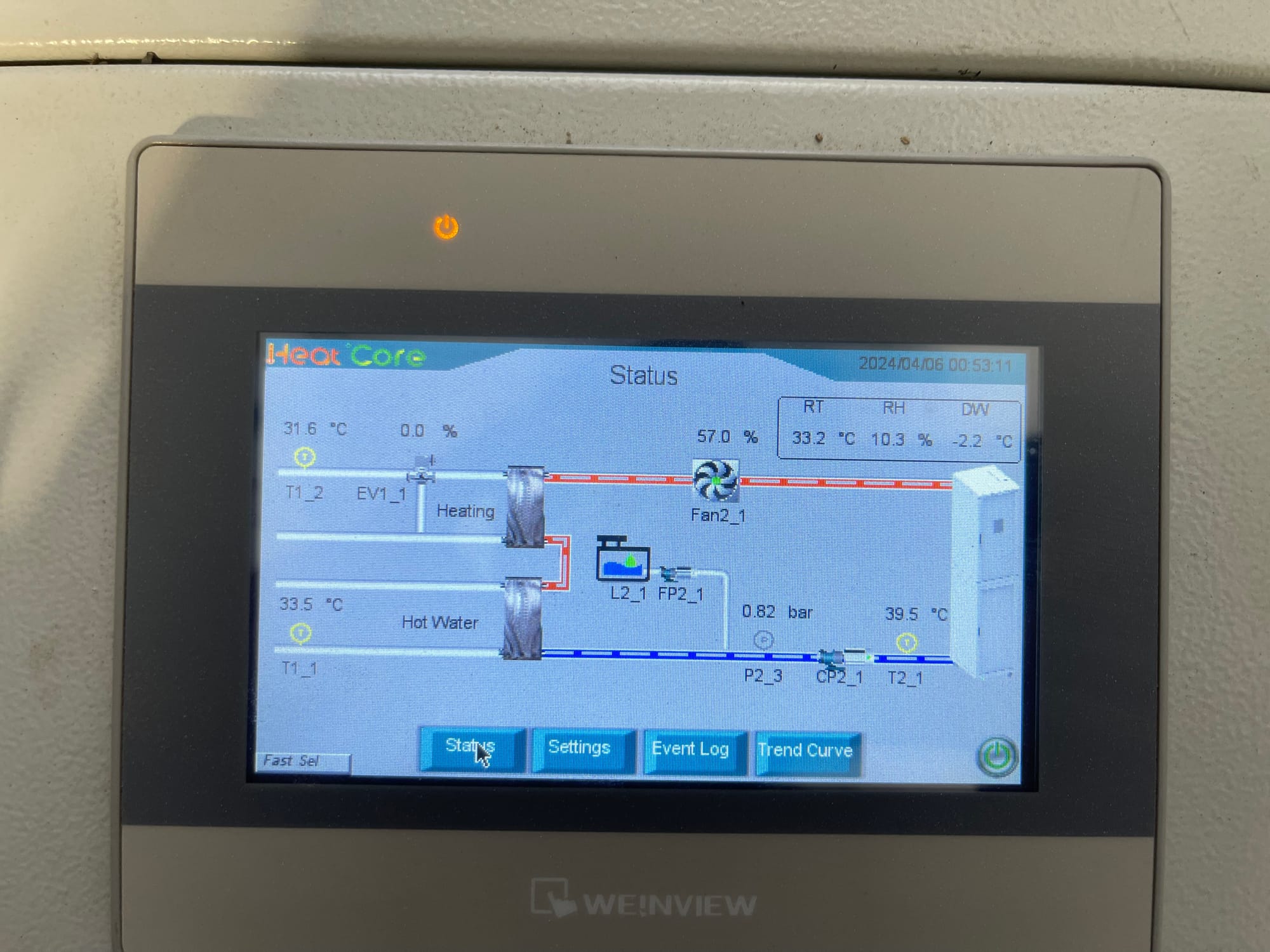

The HS20 also features an LED screen mounted atop the boiler, which displays information from the HeatCore Smart Control System (SCS). This controller manages the flow of water into the hydro-cooled miners. The home screen displays key operational data, including but not limited to:

- Heating outlet water temperature

- Control volume of water needed

- Hot water outlet water temperature

- Pump status

- Dry cooler fan speed

- Water filling pressure

This real-time information allowed us to easily monitor the HS20's performance and operational status during the testing.

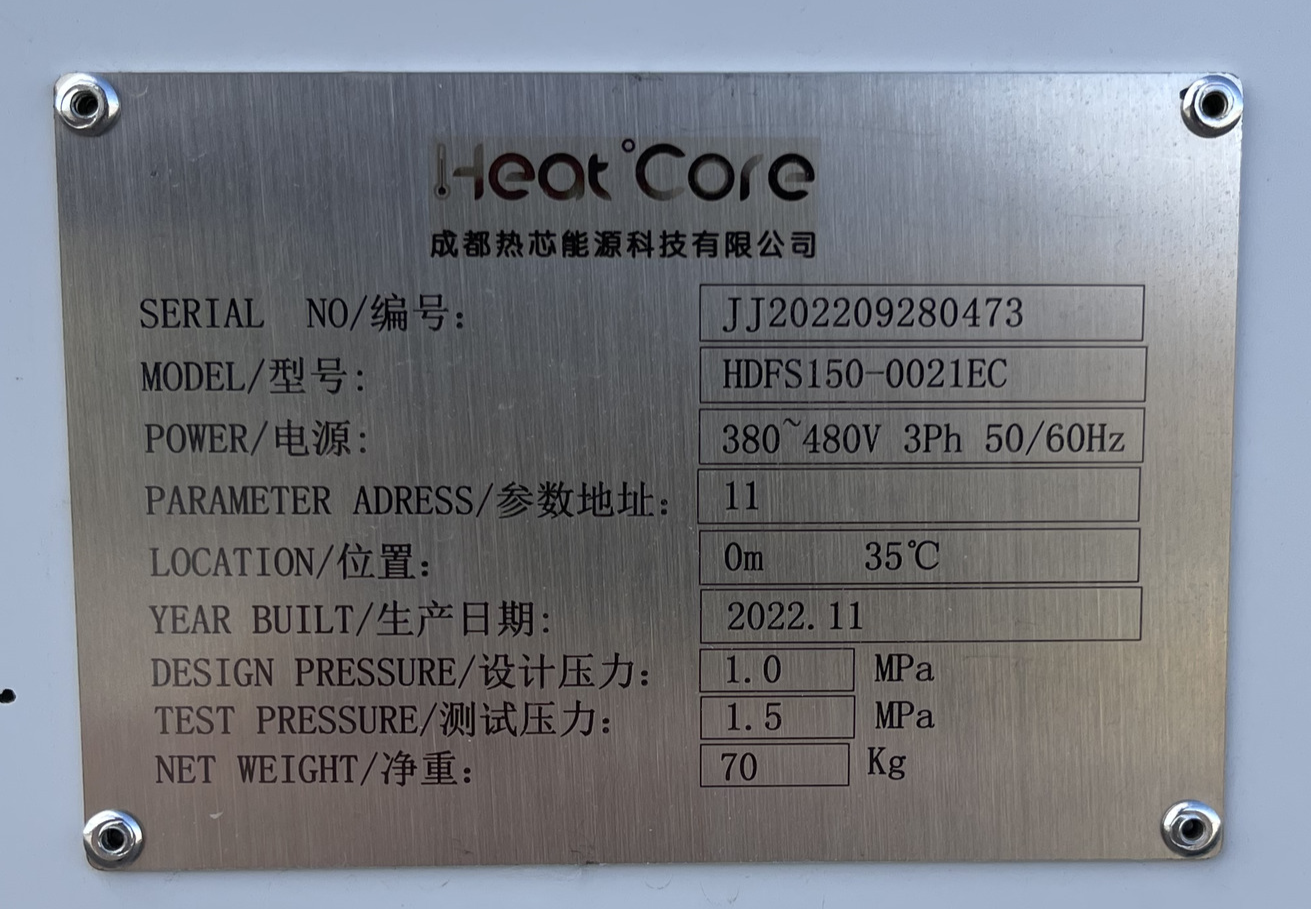

DC20 Dry Cooler

The HS20 utilizes a stainless steel DC20 dry cooler measuring 1050mm x 570mm x 855mm. This unit enables 20kW of cooling capacity to manage the HS20’s water/antifreeze temperature.

The dry cooler has a 500mm aluminum fan and generates a noise level between 52-55dB, which is about the noise level of a normal conversation. It weighs 90kg inert and 99kg when operational. The unit is designed for a maximum pressure of 1MPa and requires 3-phase power at 380-480V.

Testing the HS20 with a Whatsminer M63S Hydro Model

Introduction of M63S

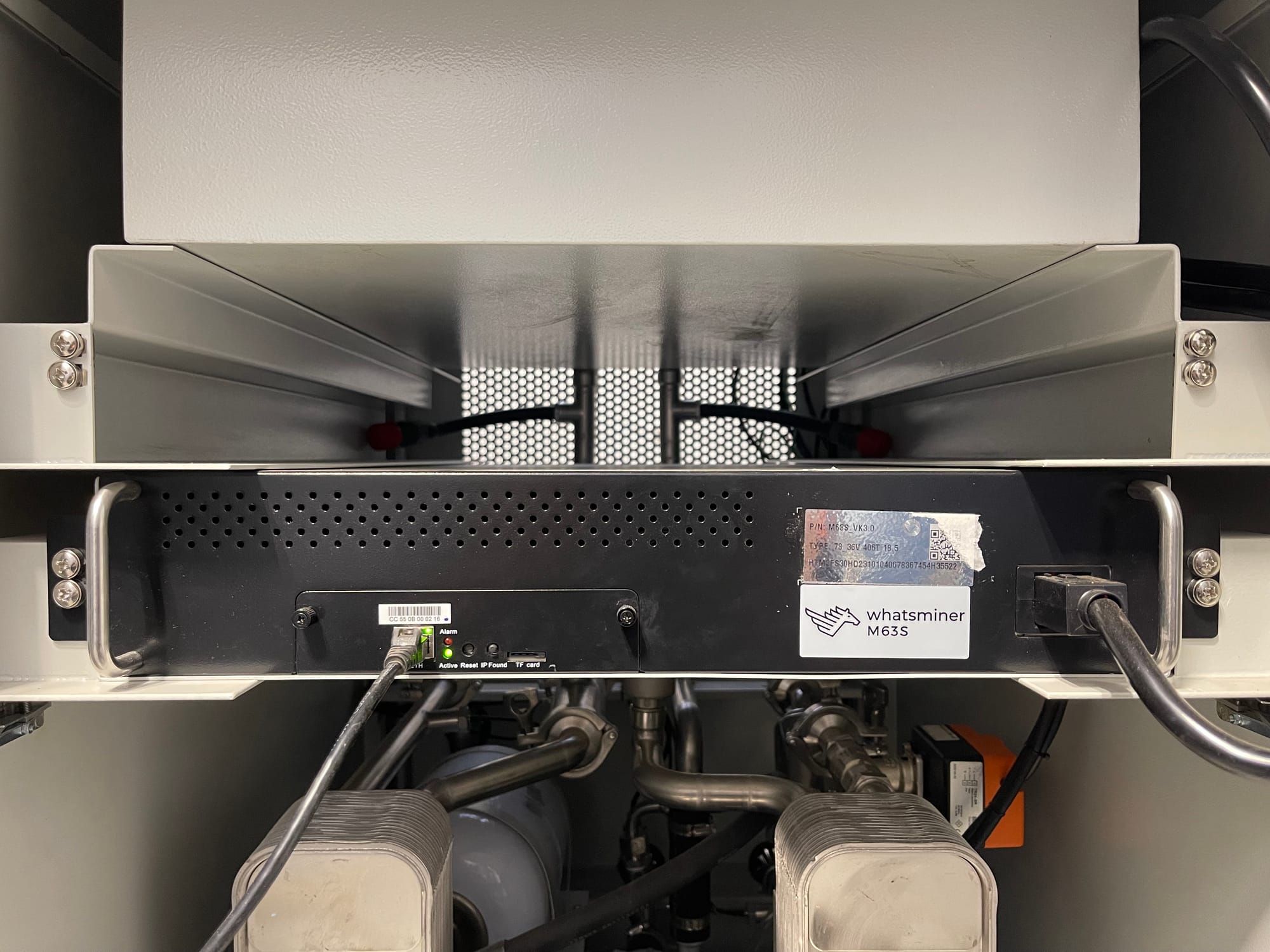

The Whatsminer M63S is MicroBT’s latest hydro-cooled miner model. The test unit we used to evaluate the HS20 has a nameplate hashrate of 406T and consumes 7511W of power. Each unit measures 86mm x 483mm x 663mm and weighs approximately 27.5kg. The M63S operates using a 380-480V power supply unit (PSU) and requires roughly 1 liter of coolant per machine.

Based on our communication with MicroBT, the manufacturer of M63S, a single-phase 220V-277V version of M63S is on the way and it’s estimated to be launched in the second half of 2024.

Important note: the M63S utilizes a unique power cable. This 9.5kW, three-phase power cable with a minimum rating of 16A is specifically customized for Whatsminer hydro units.

Unlike Whatsminer's air-cooled and immersion models as well as Bitmain's hydro models, the M63S features a distinct rack space design with an integrated PSU. While Bitmain hydro models typically incorporate four sets of corrugated inlet and outlet pipes on each hashboard and the power supply, the M63S utilizes only one set of inlet and outlet pipes, along with a set of connecting pipes located at the back of the miner.

Power-On Test

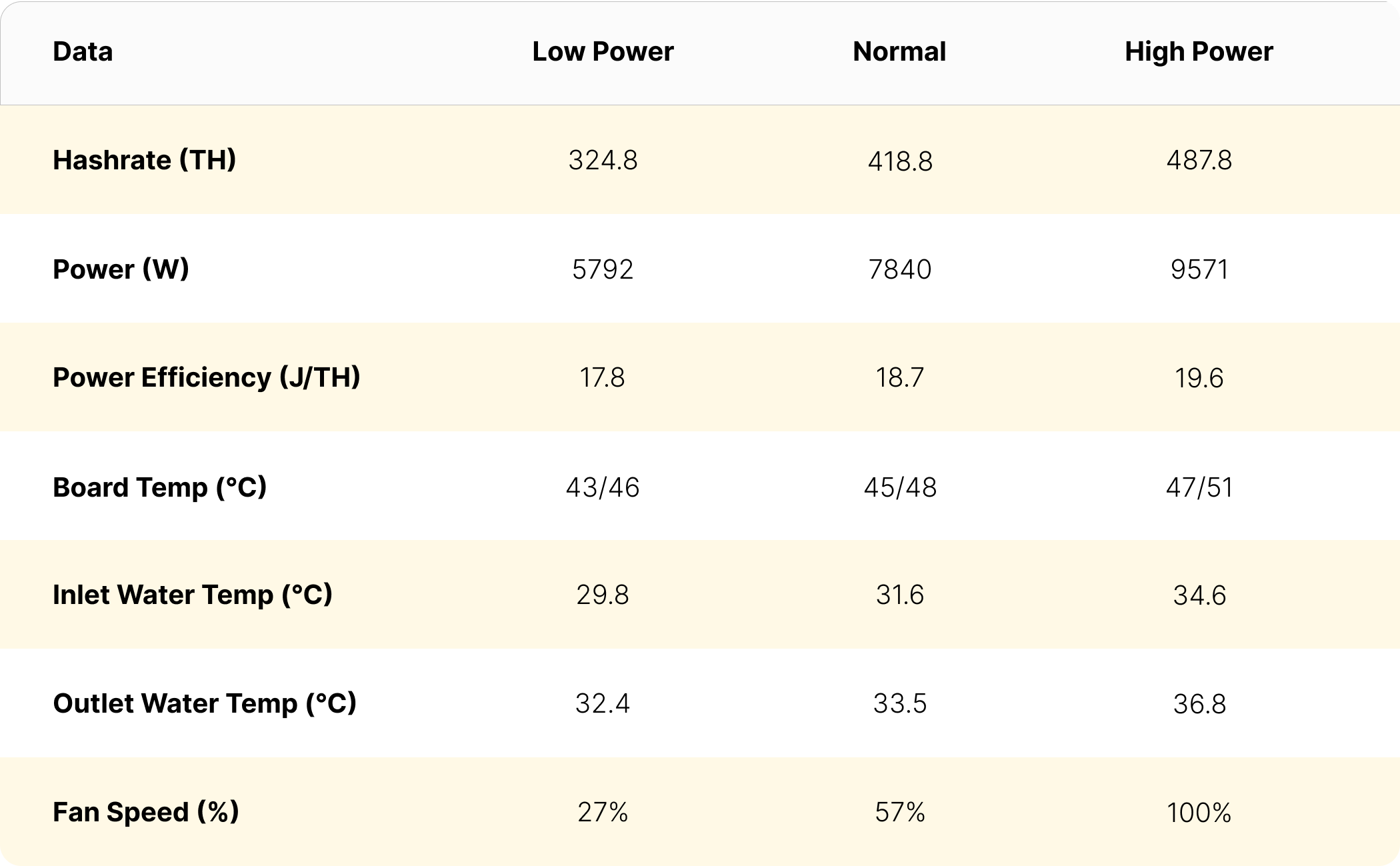

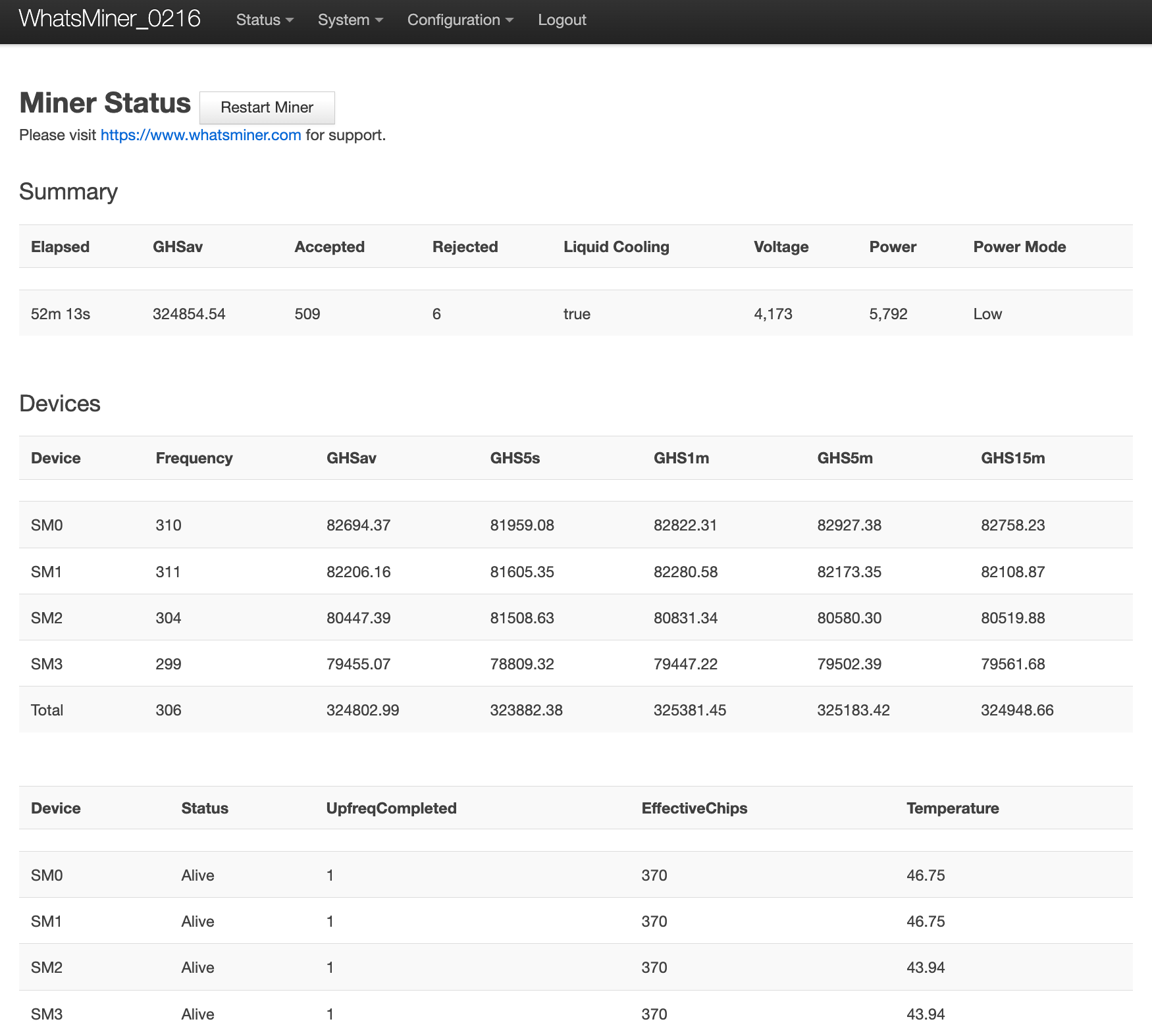

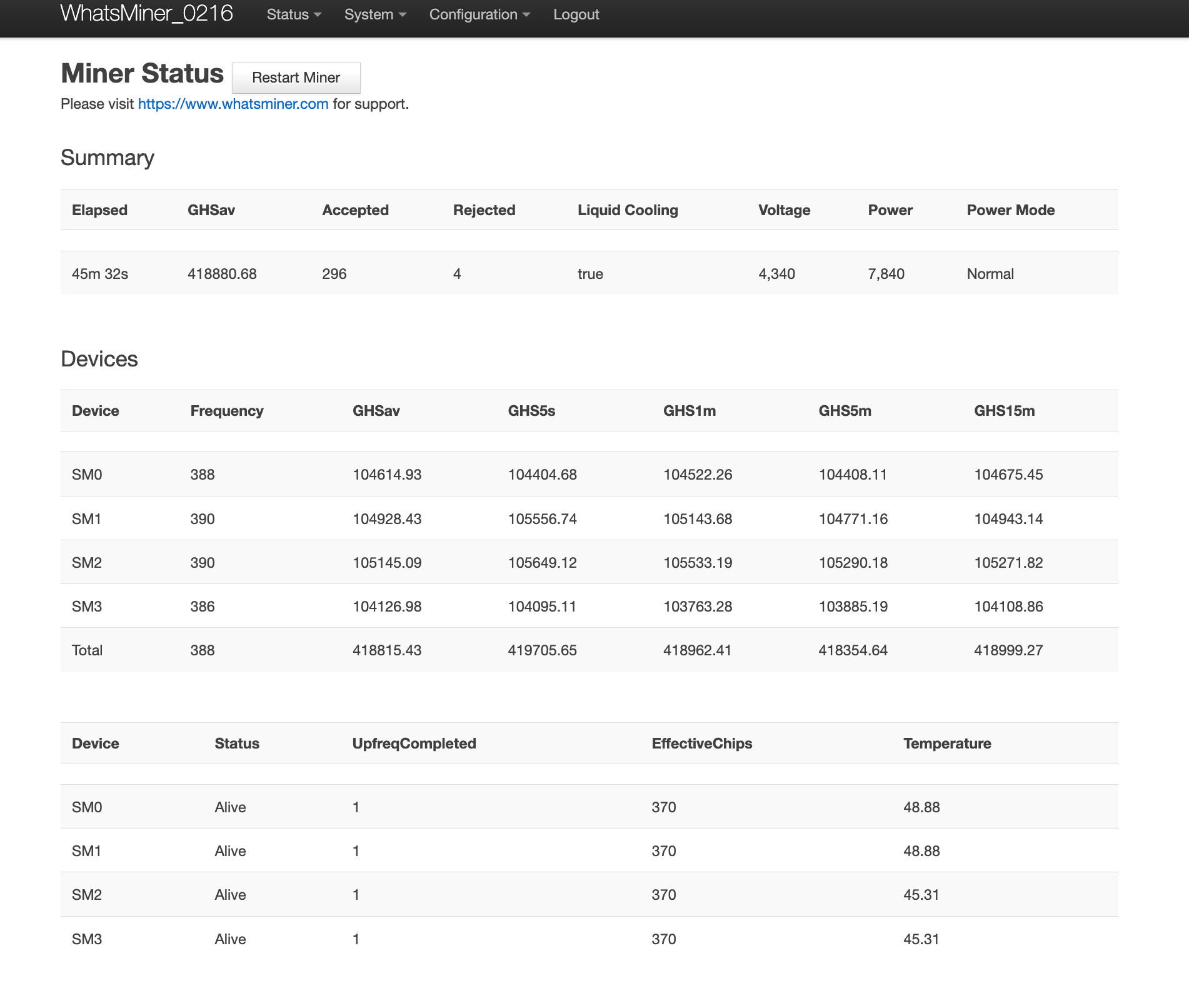

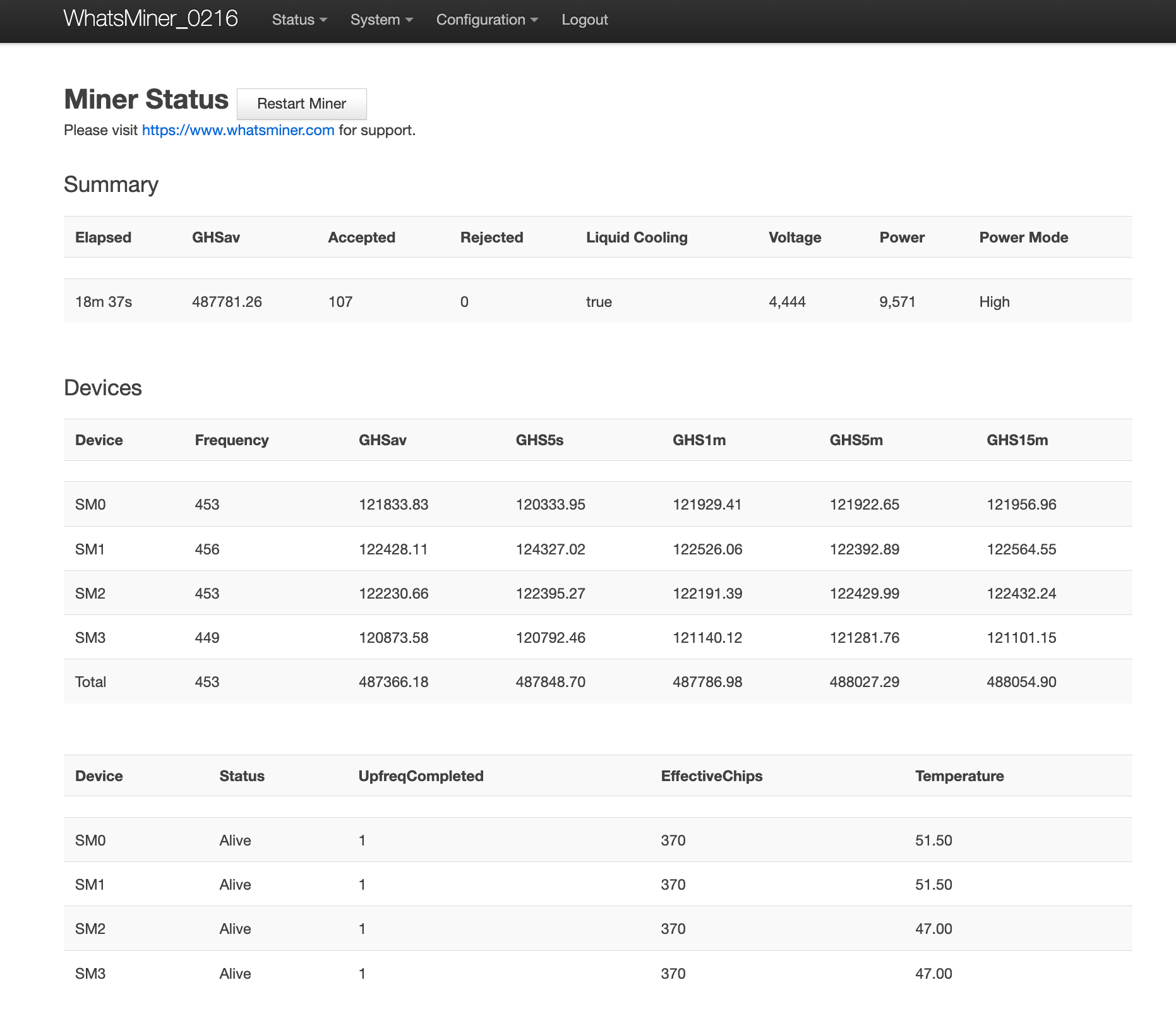

To assess the M63S’s interaction with HS20 and performance, we tested the miner in normal mode, low power mode (underclocking), and high power mode (overclocking). We monitored hashrate, power consumption, board temperature, inlet/outlet temperatures, and fan speed. The results presented below demonstrate the HS20's effectiveness:

Below are the details from the M63S’s firmware dashboard for the power-on tests:

Key findings

- In overclocking mode, the M63S revealed a significant 15% hashrate increase while maintaining a power efficiency of approximately 19.6J/TH. This showcases the HS20's ability to handle increased performance demands.

- The HS20 system shines with its efficient cooling, exemplified by the fact that, for our test, the temperature difference between the water inlet and outlet was a mere 2°C. Notably, MicroBT recommends a maximum temperature difference of around 7°C, which highlights the HS20's impressive thermal management capabilities demonstrated in our testing. However, the M63S power consumption of 7511W translates to roughly 8.4 kW of heat generation (assuming a power efficiency of 18.5J/T). This leaves a significant buffer for the HS20's cooling capacity when only running one M63S with HS20. Therefore, further heat load tests are needed with 2 units of miners running with HS20 to see how it effectively cools the water and prevents overheating.

- The HS20's ability to generate hot water as a byproduct of mining operations opens up possibilities for reducing reliance on conventional water heating systems. With an outlet water temperature exceeding 36°C in our testing, the HS20 could potentially contribute to a hydronic heating system, supplementing a home's heating during colder months. It could also be used to pre-heat water for domestic hot water needs, reducing the energy demand on a traditional water heater. Yet, the effectiveness of hot water integration depends on several factors, including the user’s specific needs, local climate, and the size of the home. We later learned that with additional steps installing the latest firmware, the HS20 system is able to generate an outlet water temperature of 70℃ with an inlet temperature being adjusted around 55℃.

- By default, when switching between miner modes (e.g. normal to low power), the miner will undergo a restart and gradually ramp up from 0. It typically takes around 30 minutes for the miner to stabilize after each change. Following discussions with the MicroBT team after the test, we learned that users have the option to adjust frequency using the Whatsminer tool, allowing for overclocking or underclocking within seconds. This feature ensures that miners in certain regions can curtail power promptly when necessary.

Happy Hashing!

Hashrate Index Newsletter

Join the newsletter to receive the latest updates in your inbox.