How to Design Optimal Airflow for a Bitcoin Mining Facility

In this guide, we walkthrough best practices and considerations for Bitcoin mining airflow management.

Bitcoin mining secures the bitcoin ledger by validating transactions. Although early miners started with mining on personal computers, bitcoin mining is now almost exclusively done with highly specialized ASIC mining machines.

This is a guest post from Aviral Shukla of Altair Bitcoin Mining Solutions, which was syndicated from Altair's blog. You can find the original post here.

These high-powered ASIC miners produce a lot of heat and typically use active air cooling which can be noisy. At Altair, we have been mining bitcoin since 2016 and have learned a lot over the years. I’m writing a multi-part series focused on the design of bitcoin mining facilities. This post is focused on airflow management related design aspects of bitcoin mining farms. Dielectric immersion cooling and water cooling are also gaining popularity, but are out of scope for this post.

Affordability, mobility & durability makes shipping containers a great option for building a mining farm. However existing metal buildings, sheds, and outbuildings can also be used for mining bitcoin. The design recommendations and calculations here can be used for buildings, pods, and mining containers.

Why is cooling for Bitcoin mining so important?

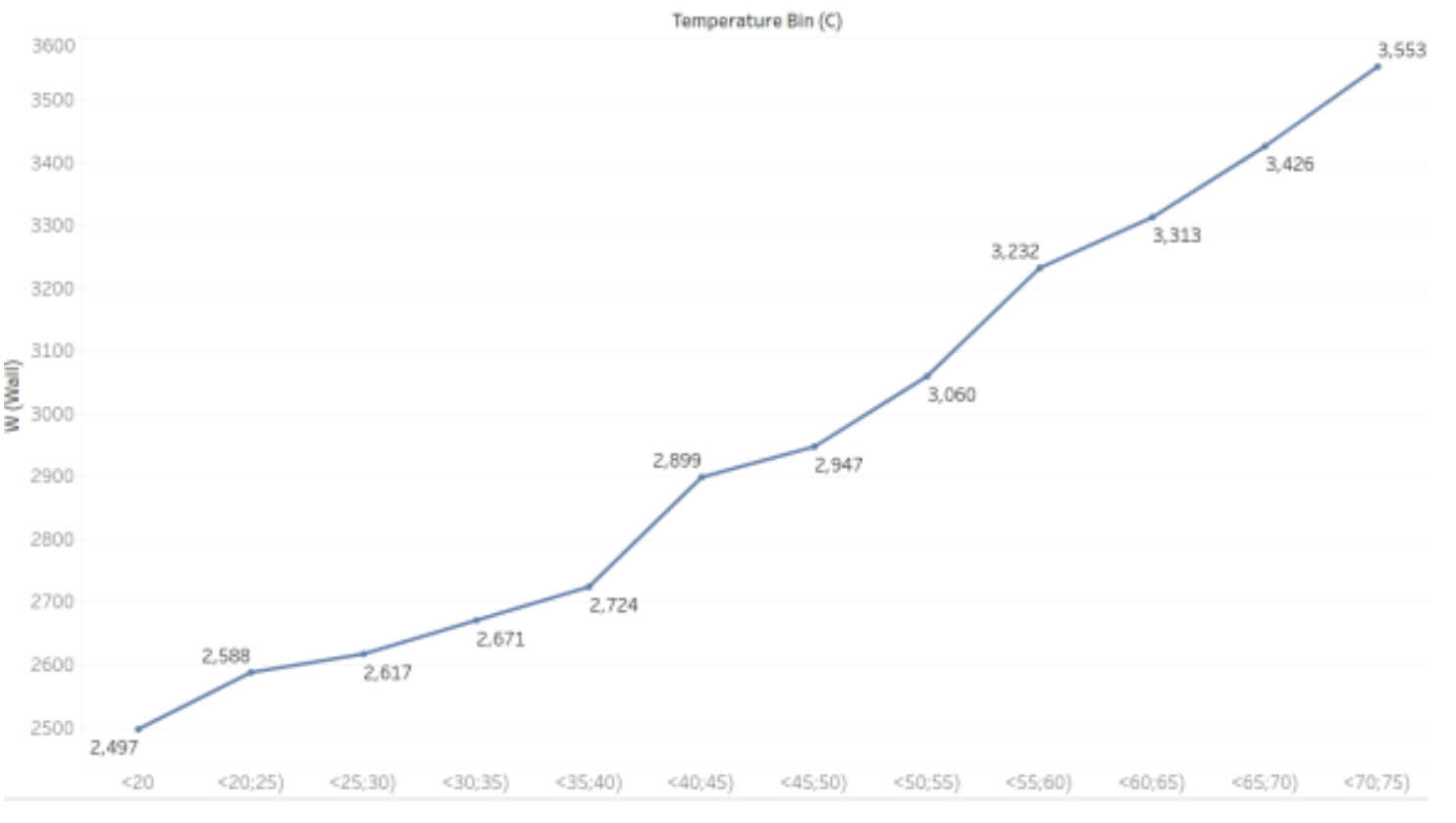

ASIC miners are programmed to throttle hashrate and eventually shut down when hashboard temperatures get too high, to prevent damage to the miner. Additionally, research from Braiins has shown that mining efficiency (Joules/Terahash) can be improved by as much as 30% with better cooling. The chart here shows a change in efficiency from 24 J/TH at 20°C to 34J/TH at 75°C at a constant hashrate. Optimal ventilation also reduces air filter maintenance and mitigates condensation related damage to equipment.

Bitcoin mining is a competitive business. Running an efficient mining operation through good design is critical for minimizing downtime and repair costs thereby increasing profitability.

Sizing air exhaust and intake

Exhaust

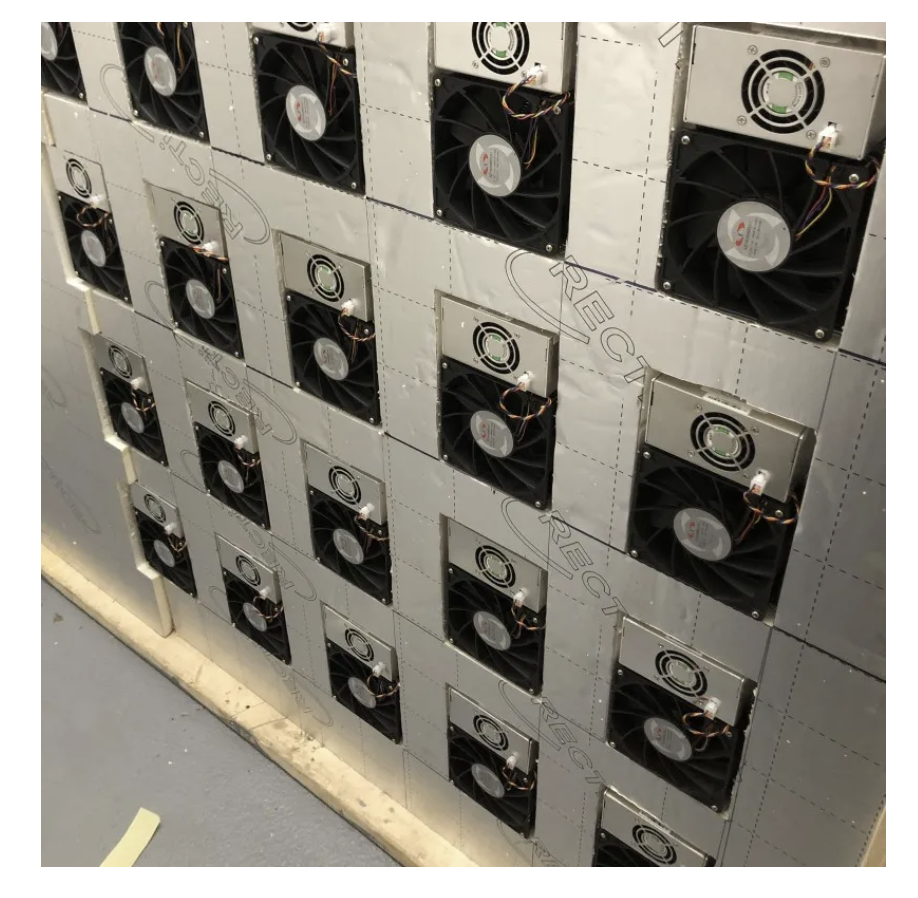

ASIC miners use electrical power to perform hashing calculations. This process converts electrical energy into thermal energy, which is transferred from the ASIC chips to the heat sinks. ASIC miners use a combination of air intake and exhaust fans to cool the heat sinks.

Most ASIC miners can run on ambient air under 100 °F, without the need for expensive air conditioning. Hot exhaust air from the miners is typically around 130-180 °F. It is important to prevent the backflow of this hot air to the air intake. The key to preventing overheating of the mining facility is providing sufficient exhaust airflow out of the building. This exhaust airflow volume has to be equal to the sum of exhaust airflow from all miners.

The calculator on the right can be used to determine the total exhaust airflow necessary to cool the mining facility, based on the number of miners and airflow through each miner. This exhaust flow has to be supported by multiple exhaust fans that cool the building. For example, if you need 100,000 cfm total exhaust flow, you will need five 20,000 cfm exhaust fans to cool the building.

Intake

Mining facilities need air intake openings to allow sufficient airflow to the ASIC miners. Air intake openings are fitted with louvers and/or awnings to prevent driving rain or snow from entering the facility. In addition, the openings have to be fitted with filters and screens to prevent bugs, dust, pollen, and other foreign material from entering the facility. The calculator on the right can be used to estimate the total amount of air intake area.

Evaporative cooling

Why Evaporative cooling?

Most ASIC miners are designed to operate with intake air temperature under 100°F. However, many mining facilities are located in warmer climates where temperatures might reach up to 120°F during summer months. This hot ambient air needs to be cooled before it can be used by the ASIC miners. Evaporative cooling can be used to cool intake air by 15-30°F.

How it works

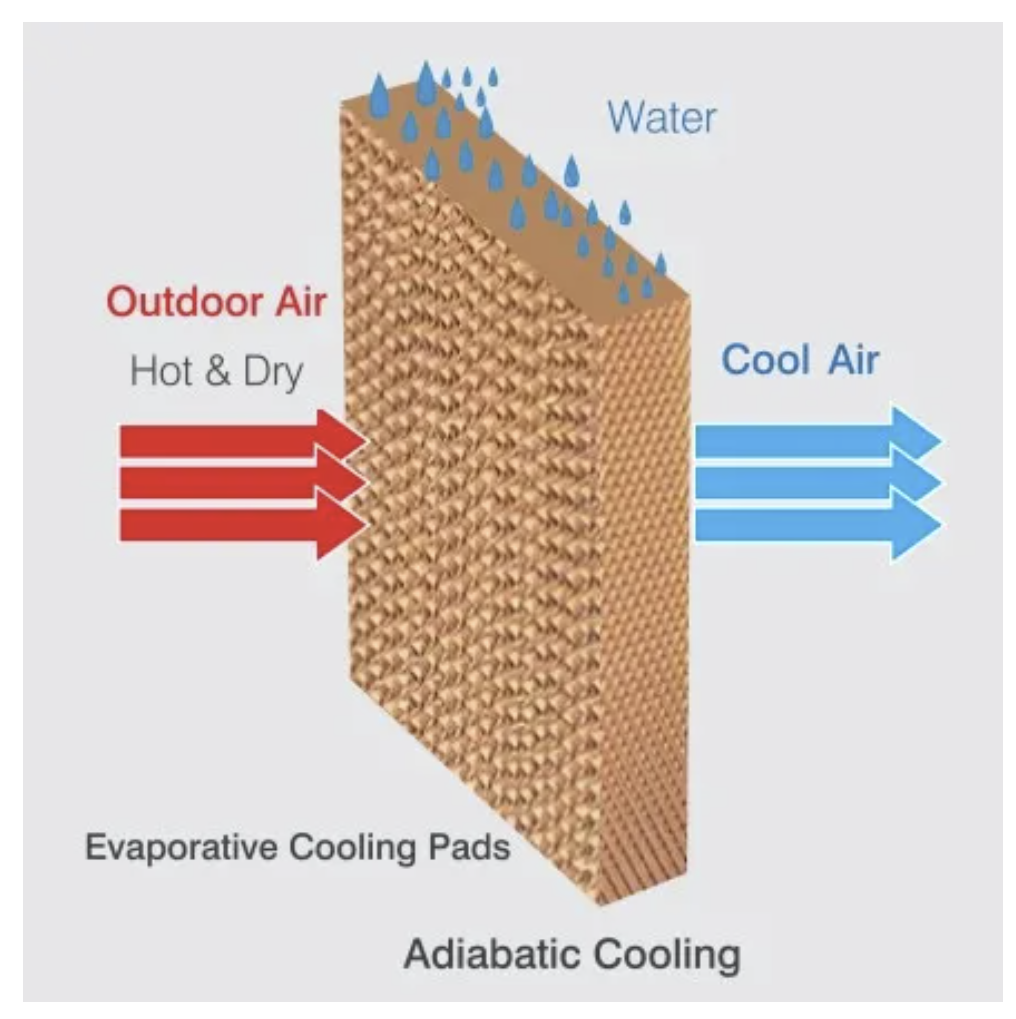

Based on the principles of evaporation, hot and dry outside air is drawn through water-soaked cooling pads. As the air is pushed through these pads, water evaporates and the heat in the air is absorbed, which lowers the air temperature. Cooling intake air by using the adiabatic effect of evaporating water is far more energy efficient and therefore cost-effective, than using compressor-driven mechanical cooling used in air conditioners. In fact, the operating costs can be up to 80% lower. Evaporative cooling also provides additional filtration benefits by removing dust and pollen from the air.

Effectiveness and caveats

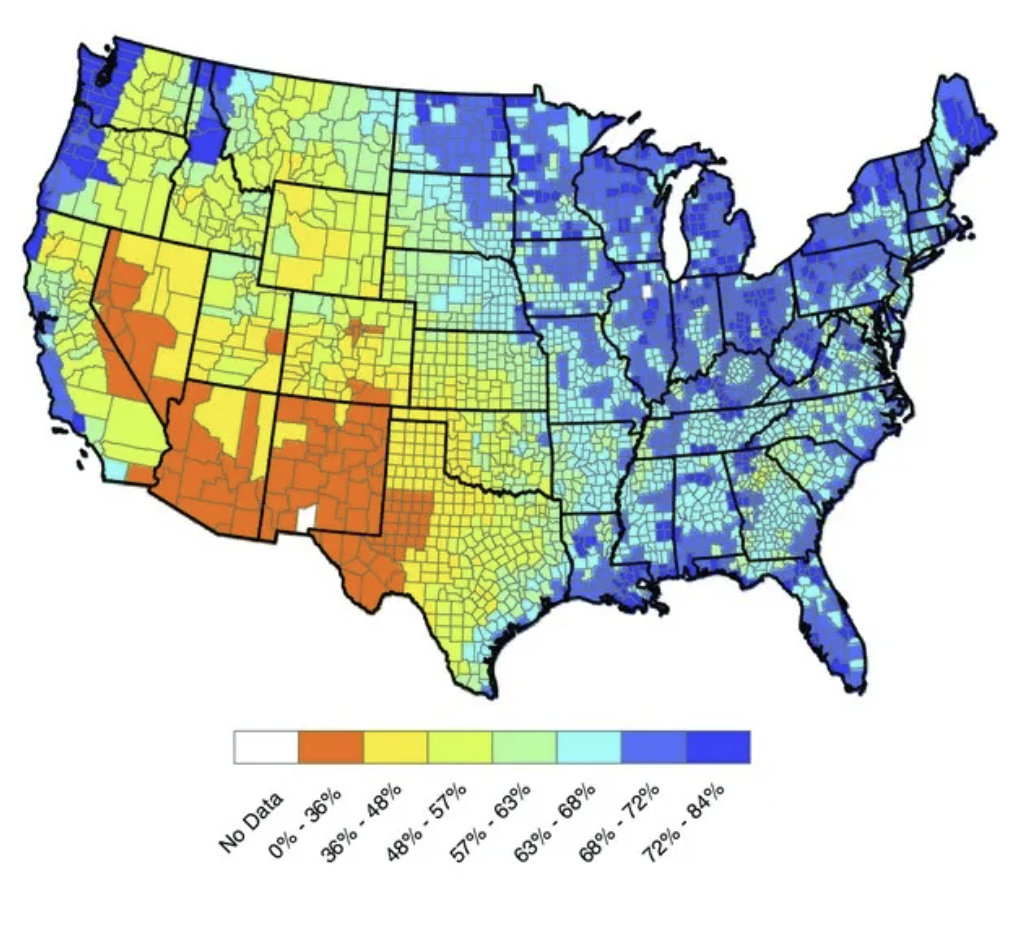

Since the cooling effect is provided by removing heat from air by evaporating water, the effectiveness of evaporative cooling is highly dependent on the humidity and temperature of air. Hot and dry air provides the most evaporation and is, therefore, cooled most effectively. Evaporative cooling is not effective for coastal climates and during periods of rainy weather with high humidity. Mining facilities located in orange and yellow regions of the US map here would benefit the most from evaporative cooling.

ASIC miners require < 90% relative humidity in the intake air to prevent condensation damage. Evaporative cooling will increase the relative humidity of intake air, making it especially important to closely monitor air humidity levels when using evaporative cooling. Even hot and dry locations should scale back on evaporative cooling during rainy and cold weather periods.

Separating hot & cold air

ASIC miners work best with cool intake air, and it is very important to prevent the backflow of hot exhaust air to the intake side. Insulation material based air barriers can be used to prevent this backflow. This technique is called hot aisle containment and foam board insulation available in home improvement stores is commonly used for this purpose. Since the primary mechanism of heat transfer with air mixing is convection and not conduction, the R-value and thickness of insulation material are not very important.

Moisture control & hot air recirculation

High humidity in the intake air can create problems in mining facilities. Moisture in the form of snow is easily drawn in with air, especially during winter storms. At high relative humidity levels, moisture in air can condense on cool surfaces. Condensation can also occur with a drop in air temperature or with pressure variation. Although, one might think that ASIC miners are immune to condensation since they operate at high temperatures, fluctuations in air pressure inside a miner can cause condensation at higher relative humidity levels. Additionally, any miners idling due to malfunction, will stay cool and are at a higher risk of condensation damage. High moisture can also cause damage to power distribution units, power supplies, control boards, switchgear, and other equipment. First signs of moisture problems inside a mining facility, often appear as rusting on air intake fan grills.

ASIC miner manufacturers typically recommend operating bitcoin mining facilities at relative humidity levels below 90%. Since relative humidity depends on air temperature, one of the easiest ways to reduce the relative humidity of incoming air is to heat it by mixing it with the hot exhaust air. For example, intake air at 60°F and 90% relative humidity, when heated by just 5°F, will drop to 75% relative humidity, thereby making it safe for use in mining. This method is called hot air recirculation.

Hot air recirculation can be achieved by leaving gaps in the air separation barrier, to allow for limited backflow of hot air to the cold side. This approach, however, heats up the incoming air and reduces mining efficiency (Joules/Terahash). It is essential to control the backflow precisely, to prevent condensation without a large increase in cold intake air temperature. One can also set up an automated hot air recirculation system, which can control the volume of air backflow based on intake air temperature and humidity levels.

Change in Humidity with temperature

Facility layout & engineering design

Wall exhaust vents

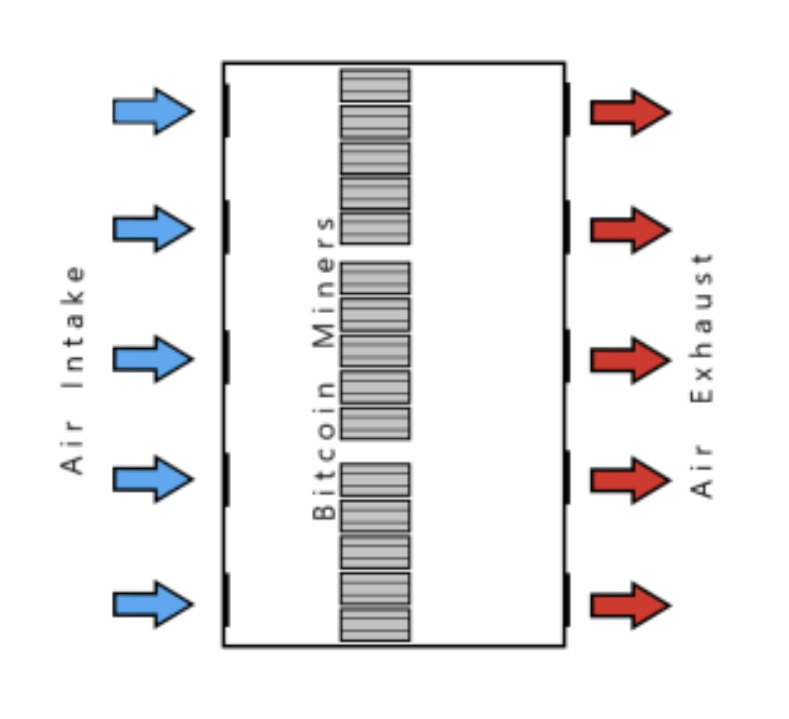

The simplest airflow design of a mining farm resembles that of a wind tunnel. Cool air enters from one side, runs through a wall of miners, and is discharged on the opposite side. Exhaust fans are needed to keep the hot air from accumulating in the building. The negative pressure created by ASIC miners and exhaust fans is sufficient to draw cool air in, without the need for installing fans on the air intake side. This airflow design is fairly common in small and medium-sized (<2 MW) mining operations and shipping container designs.

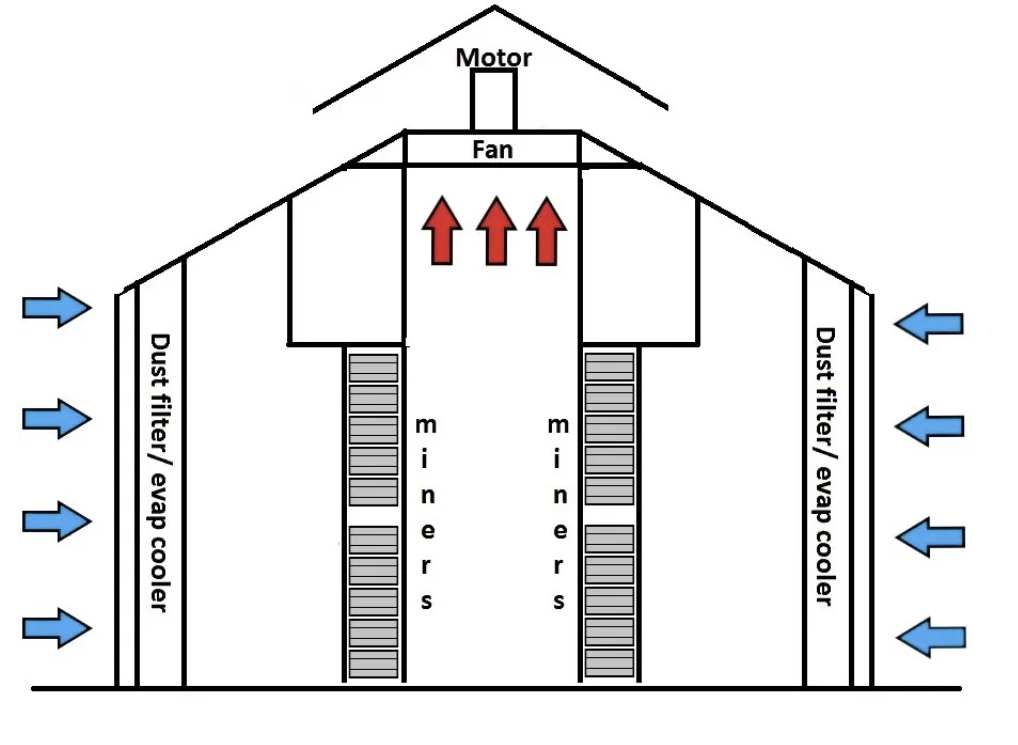

Roof exhaust vents

Roof-vented designs are steadily gaining popularity and are now commonly seen in larger mining facilities (>5 MW). Hot air naturally rises and is discharged out of the building through roof-mounted exhaust fans. This type of design supports a higher miner density inside the building, by allowing for air intake on both sides. However, roof-vented building designs are usually more capital intensive to build and maintain.

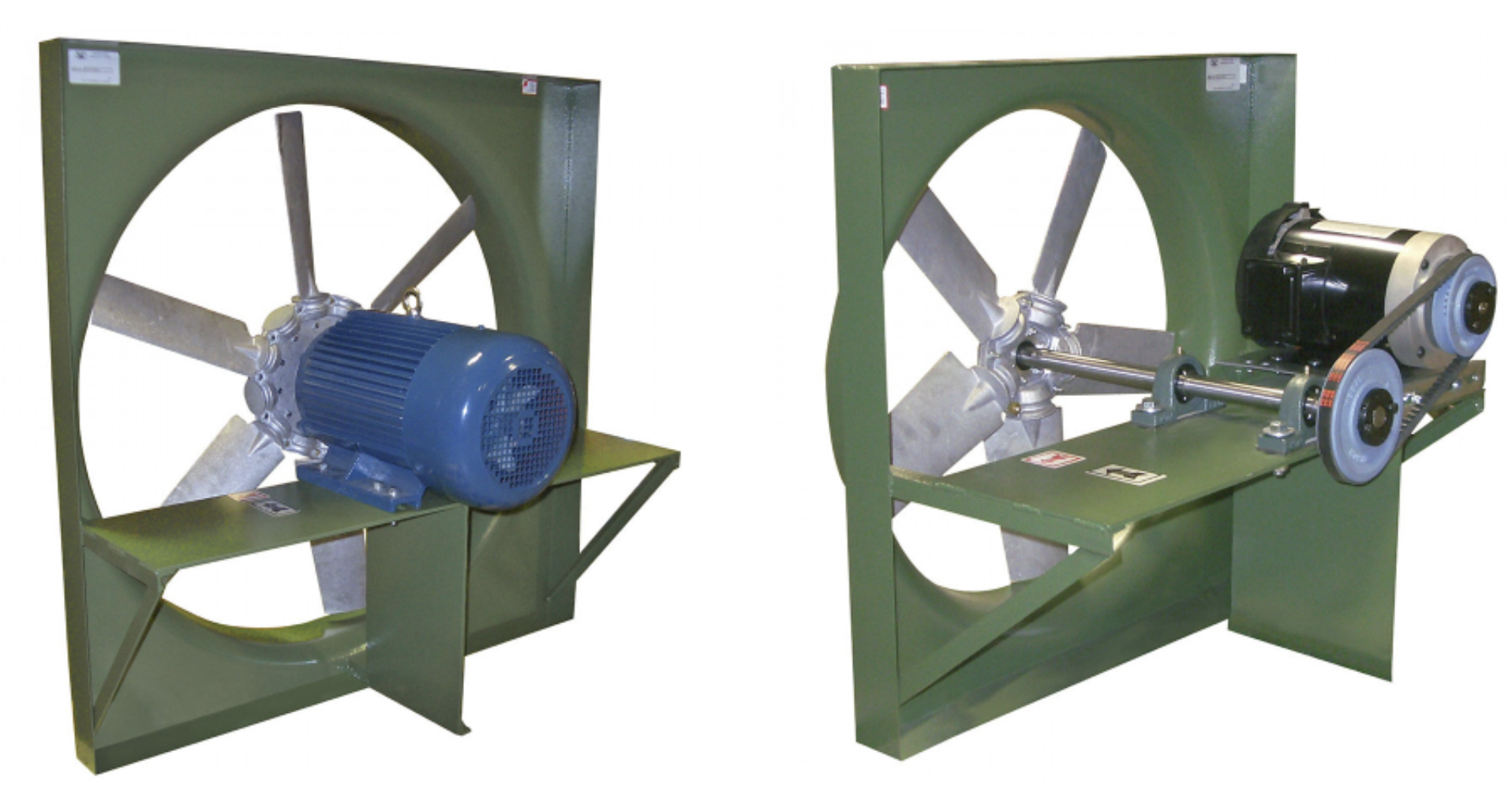

Direct drive vs belt drive exhaust fans

Direct drive and belt drive are the two major fan types and both have some pros and cons. The goal here is to cover the advantages and disadvantages of both, to help make a more informed decision.

Direct drive fans typically require lower maintenance since there are no sheaves, belts or bearings to maintain.

Belt drive fans are popular for propeller fan sizes larger than 36″. Larger belt-driven fans are usually more cost-effective. They also offer higher performance flexibility through the use of a drive package to adjust fan speed as needed.

While both these types are used in bitcoin mining facilities, direct drive fans are more popular due to their simpler design and lower maintenance overhead.

Intake design

Air intake openings can draw in rain and snow, thereby creating moisture problems inside the mining facility. Louvers alone do not provide sufficient protection against rainfall. Most new facility designs use extended roof overhangs or awnings in addition to intake louvers, to provide protection from rain and snow.

Insufficient air intake area creates high intake air velocity. This in turn creates turbulent airflow, draws in more precipitation, and leads to frequent filter maintenance. Increasing air intake area can remedy many of these issues. This can be achieved in several different ways. Thick pleated filters, increase intake surface area and have a higher free area ratio.

An increasingly popular air intake design uses multiple parallel rows of awnings mounted on the side wall of the mining facility. Filtered air intake openings are located at the bottom of the awnings. When compared to a wall intake design, this awning-based intake design can provide a much higher intake surface area. Additionally, since the intake openings are facing downward, this design is much better at filtering out dust and pollen.

Heat recovery

Traditional air handling designs assume hot exhaust air is a nuisance and focus on discharging it. In their quest to increase profitability and sustainability, bitcoin miners are now coming up with creative ways to recover exhaust heat. This heat is increasingly being used in a variety of applications such as drying wood, dehydrating produce, heating water, aquaculture, etc. Additional revenue streams provided through heat recovery applications can offset a substantial portion of operating costs for miners. Since conventional bitcoin mining facility design does not allow for heat recovery, innovations in this field will continue to drive changes in engineering and design of bitcoin ming facilities.

Final thoughts

Over the last decade, we have seen an exponential increase in the complexity required to mine bitcoin profitably. As a result, it is increasingly important for miners big and small, to optimize their mining operations. I started mining out of my basement in 2016, and have graduated to building a megawatt scale mining operation over the years. This is my attempt to share what I have learned, to demystify design aspects, and to help democratize bitcoin mining. Subscribe to the newsletter to get notified about upcoming blog posts on electrical, networking, and on other design aspects of bitcoin mining. If you have any tips, tricks, questions, or best practices to share, please post them in the comment section below. Good luck on your bitcoin mining journey!

Hashrate Index Newsletter

Join the newsletter to receive the latest updates in your inbox.